Officespace |

Louvain-la-Neuve, Belgium, 2024

|

Coworking space for Silversquare designed by Lilian van Daal.

|

Credits:

Design

|

3D concrete printing

|

Resources:

|

Phoenix |

Lyon, France, 2023

|

"Striatus 2.0: Phoenix" is a permanent, unreinforced masonry footbridge composed of 3D-printed concrete blocks assembled without mortar or reinforcement. It was built at the Holcim Innovation Centre in Lyon, France. Project developed by the Block Research Group (BRG) at ETH Zurich, Zaha Hadid Architects Computation and Design Group (ZHACODE), incremental3d (in3d), and Holcim.

Phoenix represents a step forward in the realisation of circular construction with concrete. As an iteration of the Striatus bridge built in Venice, Italy, in 2021, Phoenix shows a significant advancement in the application of an unreinforced-masonry structural logic to 3D concrete printing (3DCP), mainly on circularity, environmental impact reduction, and structural robustness aspects.

Compared to Striatus, the CO2 emissions were cut by 25%, largely due to a new concrete mix developed by Holcim, which uses locally sourced and recycled materials, and the decreased reliance on single-use materials for falsework during construction. Phoenix resulted from the partial recycling of the original blocks of Striatus.

Unlike the original Striatus, Phoenix is designed as a permanent structure. Its shallower geometry eliminates the need for steps, making it more accessible and functional for pedestrian use. The bridge also features a handrail system elegantly held in place by the thrust in the balustrade arches.

To enhance assembly precision while minimising single-use falsework components, the assembly logic of Phoenix was entirely reworked. Modular falsework components were developed that integrate a minimal timber waffle structure with standard reusable, off-the-shelf steel beams to minimise the volume of single-use timber elements. Three to six 3DCP blocks were precisely assembled on each falsework module before being lifted on pre-installed scaffolding towers.

The assembly followed a predefined sequence, starting from the centre towards the supports, where a gap of a few centimetres was left from the foundations. This strategy was adopted to control the fabrication tolerances and assembly imprecisions at midspan and push them towards the last interface with the supports, where they could be compensated by filling the resulting gap with mortar before decentering.

Compared to Striatus, the CO2 emissions were cut by 25%, largely due to a new concrete mix developed by Holcim, which uses locally sourced and recycled materials, and the decreased reliance on single-use materials for falsework during construction. Phoenix resulted from the partial recycling of the original blocks of Striatus.

Unlike the original Striatus, Phoenix is designed as a permanent structure. Its shallower geometry eliminates the need for steps, making it more accessible and functional for pedestrian use. The bridge also features a handrail system elegantly held in place by the thrust in the balustrade arches.

To enhance assembly precision while minimising single-use falsework components, the assembly logic of Phoenix was entirely reworked. Modular falsework components were developed that integrate a minimal timber waffle structure with standard reusable, off-the-shelf steel beams to minimise the volume of single-use timber elements. Three to six 3DCP blocks were precisely assembled on each falsework module before being lifted on pre-installed scaffolding towers.

The assembly followed a predefined sequence, starting from the centre towards the supports, where a gap of a few centimetres was left from the foundations. This strategy was adopted to control the fabrication tolerances and assembly imprecisions at midspan and push them towards the last interface with the supports, where they could be compensated by filling the resulting gap with mortar before decentering.

|

Credits:

Design

|

3D concrete printing

|

Additional partners

|

film studio

|

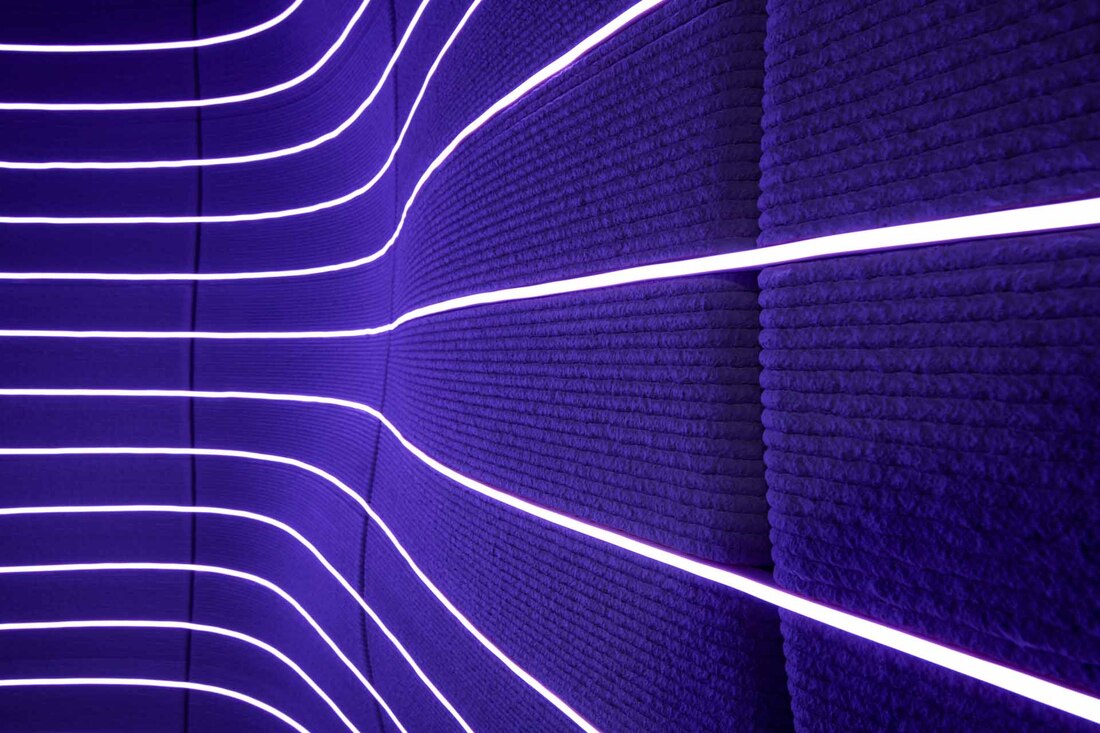

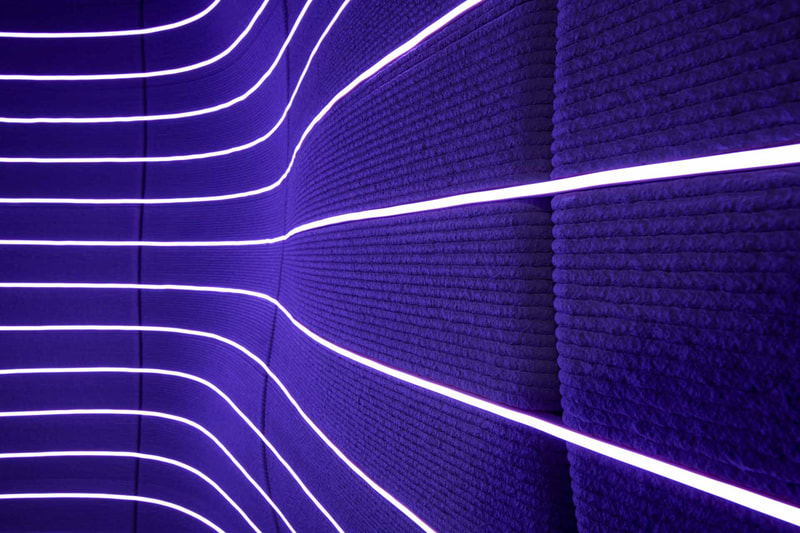

Vienna, Austria, 2022

|

Austrian Lotteries commissioned Philipp Aduatz for the design and realization of the first 3D printed film studio. In collaboration with set designer Dominik Freynschlag and 3D concrete printing manufacturer incremental3d, a new and innovative application was realized through a unique structure using additive manufacturing and the latest LED technology.

The concrete wall was printed in a total of 10 work steps using a 3D concrete printing process from an innovative special mortar based on white cement. The wall consists of a total of 60 individual segments, with 6 parts each stacked to form a segment in height. All individual parts are screwed together in each horizontal plane, so the wall can be completely disassembled and is also operationally safe during use. The main part of the lighting system are 14 LED strips inserted horizontally into prefabricated joints, which can be controlled by the RGB colour space in a variety of colours and colour gradients. By replacing the print layers with LED strips of the same thickness, the lighting technology could be perfectly integrated into the design. All LED elements are connected to the rest of the studio lighting via computer-aided control, creating an almost unlimited number of colour combinations.

Due to its material-saving properties, concrete 3D printing is considered a sustainable alternative to conventional concrete construction methods. In addition, no formwork materials are required, so waste is reduced to a minimum. If no reinforcement is used, as is the case here with the film studio, any recycling is further simplified. Components produced by additive manufacturing are not only suitable for building construction applications, but also offer completely new creative qualities and possibilities in interior design.

The wall has a total weight of 3.500 kg. The external dimensions of the wall are: 630 cm width, 330 cm depth, 230 cm height.

Due to its material-saving properties, concrete 3D printing is considered a sustainable alternative to conventional concrete construction methods. In addition, no formwork materials are required, so waste is reduced to a minimum. If no reinforcement is used, as is the case here with the film studio, any recycling is further simplified. Components produced by additive manufacturing are not only suitable for building construction applications, but also offer completely new creative qualities and possibilities in interior design.

The wall has a total weight of 3.500 kg. The external dimensions of the wall are: 630 cm width, 330 cm depth, 230 cm height.

|

Credits:

Design

|

3D concrete printing

|

Resources:

|

Striatus

|

Venice, Italy, 2021

|

An arched 3D-concrete-printed masonry bridge

A project by the Block Research Group (BRG) at ETH Zurich and Zaha Hadid Architects Computation and Design Group (ZHACODE), in collaboration with incremental3D (in3D), made possible by Holcim.

A project by the Block Research Group (BRG) at ETH Zurich and Zaha Hadid Architects Computation and Design Group (ZHACODE), in collaboration with incremental3D (in3D), made possible by Holcim.

First 3D printed and unreinforced concrete bridge

3D printing can be used to build load-bearing concrete structures that require significantly less material and no steel reinforcement or mortar. ETH architects and engineers from the Block Research Group in collaboration with Zaha Hadid Architects and other partners from industry showed how this works with a footbridge in Venice.

Millions of new buildings all over the world are being constructed with reinforced concrete, even though this type of construction generates large amounts of CO2 emissions. The steel used for the reinforcement and the cement for the concrete are especially problematic in this regard. ETH researchers have now presented a way to reduce both, in a real project.

The Block Research Group teamed up with the Computation and Design Group at Zaha Hadid Architects to build a 12-by-16-metre arched footbridge in a park in Venice – entirely without reinforcement.

Using an additive process, the construction dubbed “Striatus” was built with concrete blocks that form an arch much like traditional masonry bridges. This compression-only structure allows the forces to travel to the footings, which are tied together on the ground. The dry-assembled construction is stable due to its geometry only.

Printed in specific angles

What is completely new is the type of 3D-printed concrete, which the researchers developed together with the company incremental3d. The concrete is not applied horizontally in the usual way but instead at specific angles such that they are orthogonal to the flow of compressive forces. This keeps the printed layers in the blocks nicely pressed together, without the need for reinforcement or post-tensioning. The special concrete ink for the 3D printer was developed by the company Holcim precisely for this purpose.

ETH professor Philippe Block said: “This precise method of 3D concrete printing allows us to combine the principles of traditional vaulted construction with digital concrete fabrication to use material only where it is structurally necessary without producing waste.”

Because the construction does not need mortar, the blocks can be dismantled, and the bridge reassembled again at a different location. If the construction is no longer needed, the materials can simply be separated and recycled.

|

Credits:

Design

|

Logistics

|

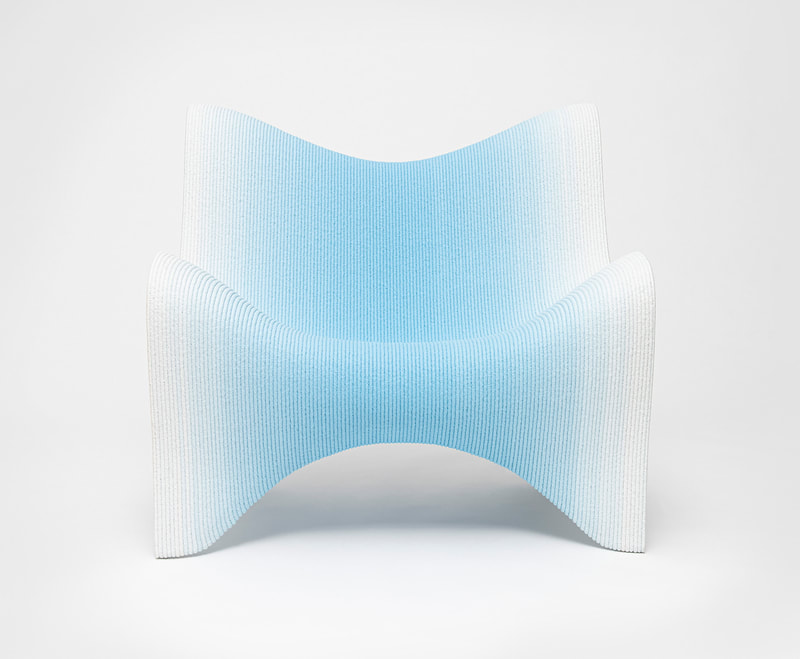

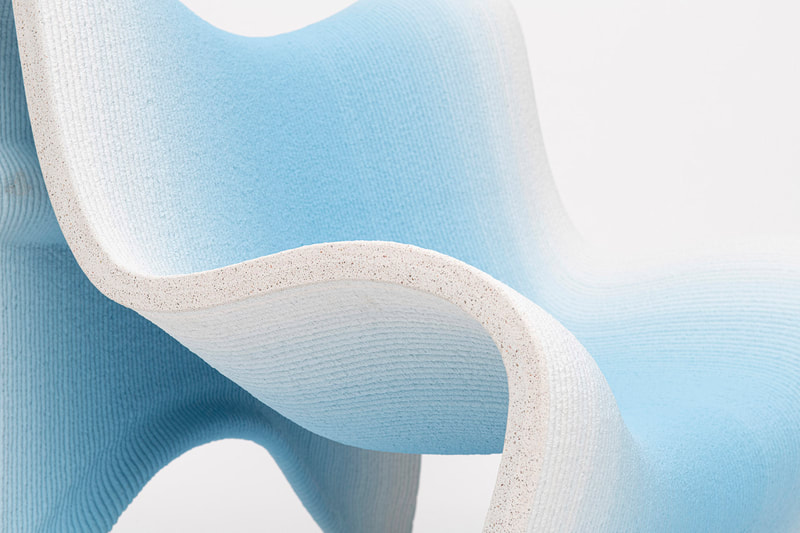

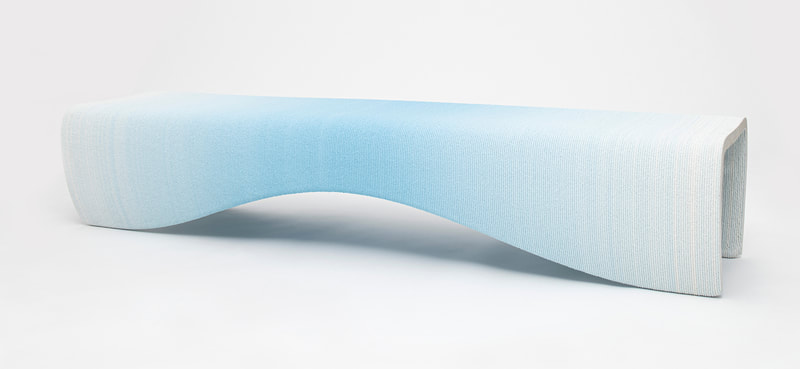

gradient furniture collection |

Sieggraben, Austria, 2021

|

The 3D printed gradient furniture collection is Philipp Aduatz latest project in the field of 3D concrete printing in collaboration with the Austrian manufacturer incremental3d.

3D concrete printing is a new and innovative fabrication technology that allows to print very large and complex structures in construction and design in a very short time period. The advantages are not only from ecological and economic reasons, no extensive mould production is necessary, but also from new aesthetic qualities. As part of a research project, incremental3d is currently exploring the dyeing of concrete. The strategy is to apply dye during the printing process directly into the nozzle and therefore reduce workload, waste and time delay. This allows a coloured design in concrete applied locally point by point and not globally, like it used to be before only possible.

The Gradient

An image gradient refers to the change of intensity of color within an image. In image processing, the gradient of an image is one of the fundamental building blocks.

Designer statement about the gradient:” For many years, I have been obsessed by the concept of a gradient which reflects elegance and harmony to me. I believe that the gradient is, in regards to the perception of the environment and its digital reflection, a fundamental design principle. It has a mathematical aesthetic and precision that I have always been admiring. With this project I want to combine the design of the gradient with different functional objects by the use of innovative fabrication technologies.” Philipp Aduatz

The Gradient

An image gradient refers to the change of intensity of color within an image. In image processing, the gradient of an image is one of the fundamental building blocks.

Designer statement about the gradient:” For many years, I have been obsessed by the concept of a gradient which reflects elegance and harmony to me. I believe that the gradient is, in regards to the perception of the environment and its digital reflection, a fundamental design principle. It has a mathematical aesthetic and precision that I have always been admiring. With this project I want to combine the design of the gradient with different functional objects by the use of innovative fabrication technologies.” Philipp Aduatz

|

Credits:

Design

|

3D concrete printing

|

cohesion |

Innsbruck, Austria, 2019

|

The COHESION pavilion was designed and erected as part of the celebrations of the 350th anniversary of the University of Innsbruck on the Campus Technik site.

Based on initial sketches and preliminary studies developed by architecture students and technical sciences students, the final design was adapted to be sited in one of the existing central water retention reservoirs of the main courtyard at the Campus Technik. In this prominent location, visible early on from the main northern entrance the temporary construction

acts as a central meeting point and signpost on campus. On the outer shell, the numbers 3-5-0 are embossed in font size 2m to clearly mark the University’s anniversary.

The structure rises westwards towards the main wind direction with a small bar table cantilevers out of the infiltration basin. From the east-facing access a slightly declining ramp leads to the interior, where integrated seating invites to linger and to relax. From the very beginning, the team had to examine in depth several constraints of 3D concrete printing

processes, such as geometry, topology, weight, structural soundness, manufacturing processes, transport and assembly. As a result, the whole continuous object was subdivided into 47 radial vertical segments, partially reinforced by steel and carbon fibres.

acts as a central meeting point and signpost on campus. On the outer shell, the numbers 3-5-0 are embossed in font size 2m to clearly mark the University’s anniversary.

The structure rises westwards towards the main wind direction with a small bar table cantilevers out of the infiltration basin. From the east-facing access a slightly declining ramp leads to the interior, where integrated seating invites to linger and to relax. From the very beginning, the team had to examine in depth several constraints of 3D concrete printing

processes, such as geometry, topology, weight, structural soundness, manufacturing processes, transport and assembly. As a result, the whole continuous object was subdivided into 47 radial vertical segments, partially reinforced by steel and carbon fibres.

|

Credits:

Design

|

3D concrete printing

|

Assembly & Construction

|

DIGITAL CHAISELONGUE |

Innsbruck, Austria, 2018

|

The Digital Chaiselongue emerged from a collaboration of Viennese product designer Philipp Aduatz with Austrian start-up company incremental3d from Innsbruck.

The sculptural design language is realized by the use of an innovative digital fabrication technology that allows to 3D print very detailed concrete geometries in a very fast time. The concept is to use the new technology developed by incremental3d for a complex freeform design by Philipp Aduatz and show the new possibilities of creating complex shapes in an application for furniture design. It is further the aim to show the synergy of the experimental and scientific approach on design by Philipp Aduatz with a company that has developed a new technology and looking for applications.

For the Digital Chaiselongue a negative mould was first 3D printed from concrete. Afterwards the complete geometry was printed in less than one hour onto the mould. To provide sufficient tensile strength, carbon fibres are inserted in sensitive areas. The seating area was finished using a UV-resistant polyurethane coating in delicate handcraft, this should demonstrate that craft and digital technologies can coexist for the purpose of innovation in the 21st century in harmony.

For the Digital Chaiselongue a negative mould was first 3D printed from concrete. Afterwards the complete geometry was printed in less than one hour onto the mould. To provide sufficient tensile strength, carbon fibres are inserted in sensitive areas. The seating area was finished using a UV-resistant polyurethane coating in delicate handcraft, this should demonstrate that craft and digital technologies can coexist for the purpose of innovation in the 21st century in harmony.

|

Credits:

Design

|

3D concrete printing

|